Roll Grooving Machine TWG-VIA

TWG-VIA roll grooving machine is designed with a unique appearance. The base can go up and down; the whole unit can be easily moved; automatic locating is available during processing. Using the folding trolley for users to move easily. In addition, the model is patent protected.

Categoria de produto:

Tel:

Email:

palavra-chave:

hydraulic roll grooving machine

foldable roll groover

Descrição do Produto

PRODUCT INTRODUCTION

● Hydraulic roll grooving machine TWG-VIA is designed for grooving 1-12" steel pipe.

● The taper knurl wheels can be changed very easily.

● The unique foldable carriage allows the machine been folded and moved by one person.

● The split-type hydraulic system coupled with foot switch enables safer and easier operation

PRODUCT SPECIFICATIONS

● Capacity: 1“-12”( Φ 33- Φ 325)SCH40 steel pipe.

1“-12”( Φ 33- Φ 325)SCH10S SCH5S SCH10 SCH5 thin wall steel pipe.

● Max. wall thickness: 10mm.

● Output RPM: 36rpm.

● G. W: 280kgs.

● Packaging size: 144x78x125(cm).

|

Standard Equipment |

|||

|

*For SCH40 steel pipe |

|||

|

Art. No. |

Description |

N.W(kgs) |

Ref No. |

|

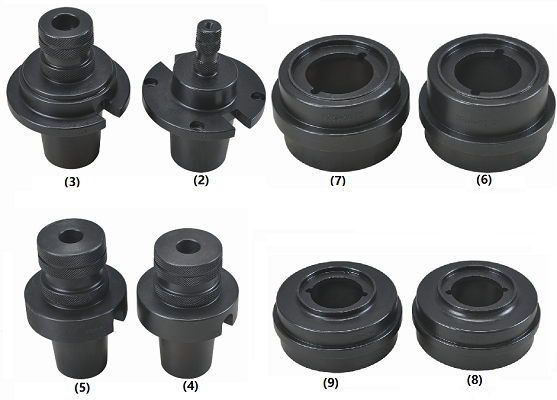

09.02.042 |

Pipe stand |

20 |

(1) |

|

03.01.12.005 |

Knurl wheel Φ 33-Φ 48 |

2.54 |

(2) |

|

03.01.12.006 |

Knurl wheel Φ 60-Φ 89 |

3.255 |

(3) |

|

03.01.12.007 |

Knurl wheel Φ 108-Φ 168 |

3.775 |

(4) |

|

03.01.12.008 |

Knurl wheel Φ 219-Φ 325 |

3.95 |

(5) |

|

03.01.12.016 |

Pinch roller Φ 33-Φ 48 |

1.425 |

(6) |

|

03.01.12.017 |

Pinch roller Φ 60-Φ 89 |

1.435 |

(7) |

|

03.01.12.018 |

Pinch roller Φ 108-Φ 168 |

0.91 |

(8) |

|

03.01.12.019 |

Pinch roller Φ 219-Φ 325 |

0.9 |

(9) |

|

*Reminding: Please select TWG-IVA if groove large number of 12 inch pipes |

|||

|

Optional Equipment |

||

|

*For SCH10S SCH5S SCH10 SCH5 thin wall steel pipe |

||

|

Art. No. |

Description |

N.W(kgs) |

|

09.03.045 |

Thin wall knurl wheel Φ 33-Φ 48 |

2.545 |

|

09.03.046 |

Thin wall knurl wheel Φ 60-Φ 89 |

3.22 |

|

09.03.047 |

Thin wall knurl wheel Φ 108-Φ 168 |

3.805 |

|

09.03.048 |

Thin wall knurl wheel Φ 219-Φ 325 |

4.01 |

|

Motor Parameter |

||

|

Phase |

Voltage |

Frequency |

|

Single phase |

110/120/220/230/240V |

50/60Hz |

|

Three Phase |

220/380/ 415/ 440V |

50/60 Hz |

PRODUCT DETAILS

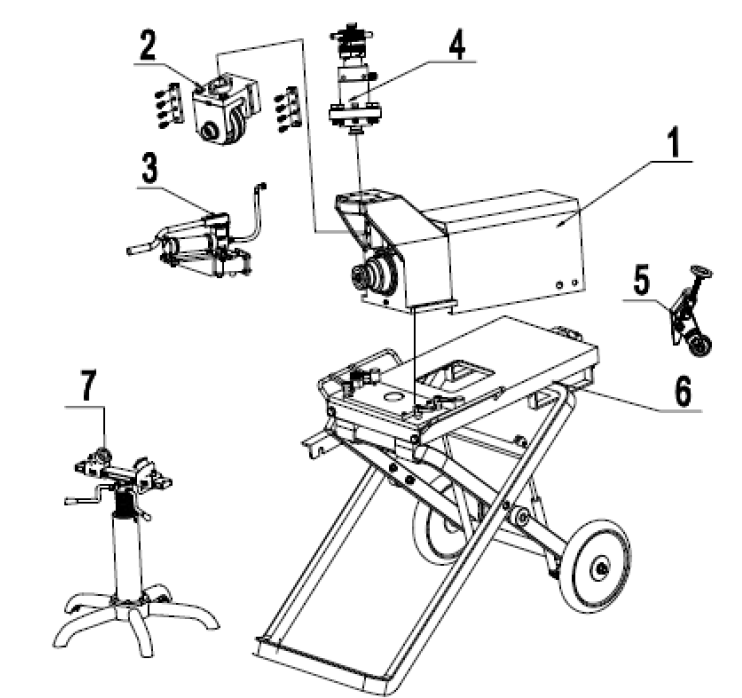

1.Power unit assembly.

It powered by 1500W reducing motor.

2.Pinch roller frame assembly.

A rotating spindle driven by a reducing motor through an internal spline groove, contributing to the reduced loss of mechanic power.

3.Oil pump assembly.

The feeding movement is realized by manual hydraulic system.

4. Oil tank assembly.

5. Wheel frame assembly.

The guide wheel helps the steel pipe to avoid shaking during the rolling groove.

6. Rack assembly.

The base can go up and down; the whole unit can be easily moved; automatic locating is available during processing.

7. Hi-support assembly.

The bracket shall be placed at a position equal to 3/4 of the length of whole pipe. Turn bracket handle to make the pipe be horizontal or the other end close to the bracket be 1-2 degree lower.

Página anterior

Próxima página

Previous page

Next page

PRODUTOS RELACIONADOS

Roll Grooving Machine TWG-VIIA

1" - 12" Steel Pipe

18" - 60" Steel Pipe

1" - 8" Steel Pipe

2" - 12" Steel Pipe

Fitting Grooving Machine TWG-15A

1.5"-12" elbows and T-fittings

PRODUTOS RELACIONADOS

Roll Grooving Machine TWG-VIIA

1" - 12" Steel Pipe

Inquérito Agora