Notícia

12

2022

-

08

Grooved Piping Connection Technology: Quality control for pipe cutting

Autor:

Tuwei

Page views:

As we all know, grooved connection technology has high requirements on the pipe end. If the pipe end is not handled properly, it will directly affect the quality of the groove, Which affects the installation quality of the pipe. Well, it is necessary to do a good job in the quality control of the pipe cutting.

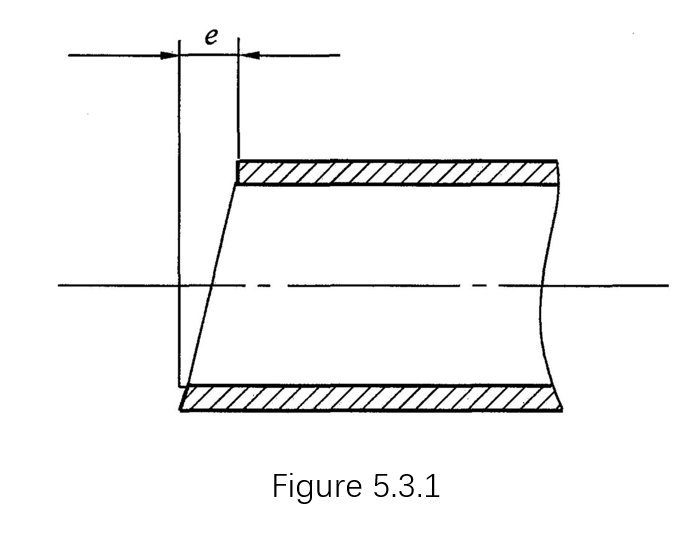

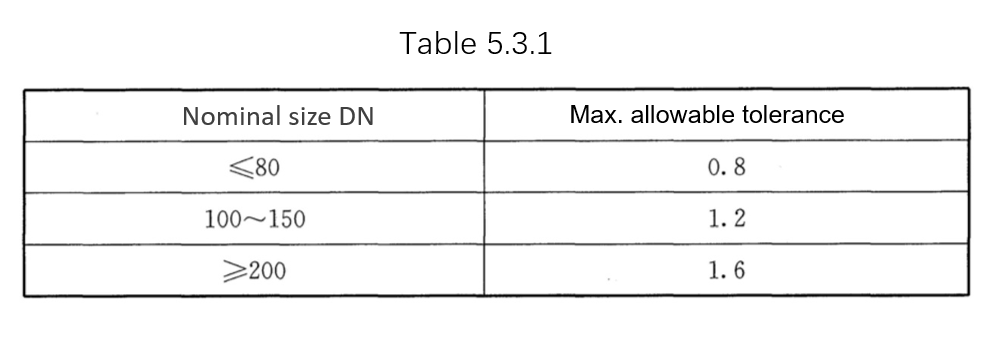

(1) Square cut ends tolerance

Before cutting the pipe, the outer diameter of the pipe should be calibrated according to the piping diagram, and the error of the outer diameter wall thickness should be within the allowable tolerance range. The cutting end shall be perpendicular to the central axis of the pipe, and Square cut ends (Figure 5.3.1) shall not be greater than the value specified in Table 5.3.1.

(2) Standard of pipe cut

After pipe is cut off,the cut should be smooth and free of cracks, bumps, shrinkage, slag, oxide .The end should be perpendicular to the pipe axis, and the outer diameter error should not exceed 1% of the outer diameter of pipes. When the nozzle is not round, it should be rounded, the wall thickness should be uniform, and the surface dirt, paint, rust, debris should be removed.

(3) Pipe cutting method

It is best to choose a non-reducing pipe cutting machine for pipe connected by grooved fitting, in order to ensure the smooth cut For pipe cutting tools, it is better to use special hydraulic pipe cutting machine.

The above are Quality Control for pipe connected with Grooved fittings, Victaulic-Tuwei company has been deeply involved in the pipe tools industry. Roll grooving machines, pipe cutting machines, hole cutting machines, pipe threading machines and other products developed by Victaulic-Tuwei receive a good reputation because of its high quality and good performance.

[palavras-chave]

standard of pipe cut,square cut ends tolerance,pipe cutting method,pipe cutting machine

Previous page

Próxima página

Página anterior

Próxima página

NOTÍCIAS RELACIONADAS

PRODUTOS QUENTES